Kinarm

Brain Injury Recovery

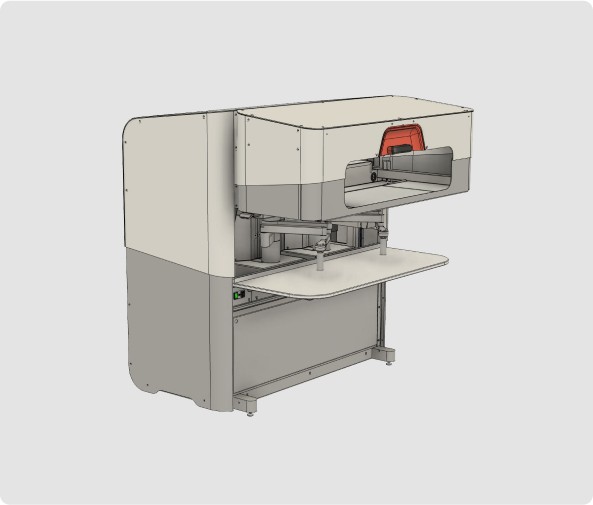

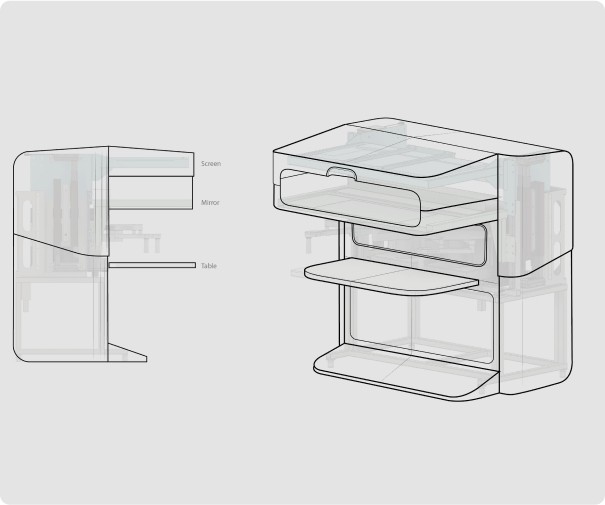

Brash partnered with Kinarm, a research facility specializing in sensory, motor, and cognitive brain function studies, to develop a large, high-performance robotic enclosure. Collaborating closely with Kinarm’s team, Brash’s designers and engineers designed, prototyped, and tested a proof-of-concept, which was then refined for manufacturing. Working directly with manufacturers, Brash optimized costs for the large-scale part while integrating branding, assembly instructions, and CMF into the final production package.

Understanding manufacturing costs and product scale.

Brash used cost-effective aluminum and sheet metal bending to create a low-cost prototype, enabling design validation before full-scale manufacturing.